|

KingMetal Precision Industrial Co.,LTD

|

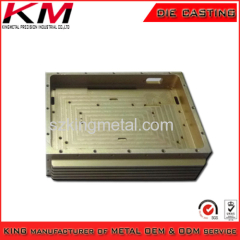

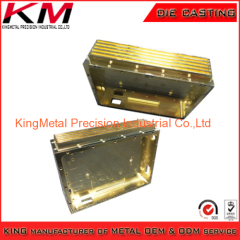

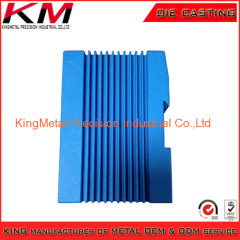

ADC12 customized manufacture painting aluminum die casting remote control case

| Payment Terms: | T/T,L/C,D/A,D/P,WU;Paypal,MoneyGram |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Aluminum Casting

OEM and ODM service

Offer various surface finish

Reasonable price and good quality

On time shipping with suitable packaging

The main die casting alloys are: zinc, aluminum and magnesium.Generally,the material including:aluminum alloy A380,A360,ADC12,ADC10,zinc 3# and zinc 5#. The following is a summary of the advantages of each alloy:

Zinc: the easiest metal to cast; high ductility; high impact strength; easily plated; economical for small parts; promotes long die life.

Aluminium: lightweight; high dimensional stability for complex shapes and thin walls; good corrosion resistance; good mechanical properties; high thermal and electrical conductivity; retains strength at high temperatures.

Magnesium: the easiest metal to machine; excellent strength-to-weight ratio; lightest alloy commonly die cast.

Maximum weight limits for aluminium, brass, magnesium, and zinc castings are approximately 70 pounds (32 kg), 10 lb (4.5 kg), 44 lb (20 kg), and 75 lb (34 kg), respectively.

The material used defines the minimum section thickness and minimum draft required for a casting as outlined in the table below. The thickest section should be less than 13 mm (0.5 in), but can be greater.

| Metal | Minimum section | Minimum draft |

| Aluminium alloys | 0.89 mm (0.035 in) | 1:100 (0.6°) |

| Brass and bronze | 1.27 mm (0.050 in) | 1:80 (0.7°) |

| Magnesium alloys | 1.27 mm (0.050 in) | 1:100 (0.6°) |

| Zinc alloys | 0.63 mm (0.025 in) | 1:200 (0.3°) |

Our die casting workshop

Thanks for your patient reading.This is Sandy from KingMetal.

Anything we can do for you,please contact us.

Skype ID :sales3-kingmetal

E-mail:sales3@szkingmetal.com

Tel:+86 755 84111279 Cel:+86 13531671350